Polyimide/PI film for FPC flexible printed circuits boards carrier

Short Description:

Product Detail

FAQ

Product Tags

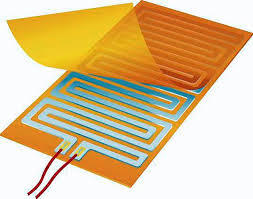

The flexible printed circuits boards high temperature carrier film, is made of a high-performance polyimide film coated with special adhesive, which is suitable for press protection for FPC flexible printed circuits boards.With silicon-free release film, you don’t have to worry about the moving of it. There is no residue, no trace and low pollution when the products attached to the FPC. We increase its stiffness by using the carrier film, get the protective effect of the FPC substrate at subsequent stations, thus obtain additional mechanical stability. The way of softness and hardness combination makes it possible to process ultra-thin aluminum foil, and prevent wrinkling and defacement effectively during the production of flexible circuit boards and processes. It is a unique combination of low shrinkage, no curl, no residue, easy to peel off and can withstand 180-200℃.The available thickness includes 36、50、75、100 and 125μm,the width and adhesive strength can be customized upon your request.

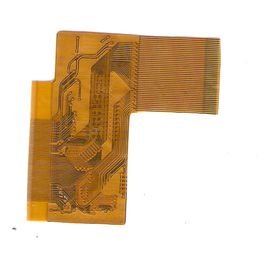

The Flexible Printed Circuit Board,which is short for FPC and is also called Flexible Board, is a kind of printed circuit board made of soft insulated-basis material(commonly polyimide or polyester film). It has many merits compared with Rigid PCB,such as bending, winding and folding freely. The FPC can reduce the volume of electronic products and meet the requirements of electronic products, helping to develop into high-density, small-size, high reliability ones. Nowadays, FPC have been widely used in in the aerospace, military, mobile communications, notebook computers, computer peripherals, PDA, digital cameras and other fields or products.

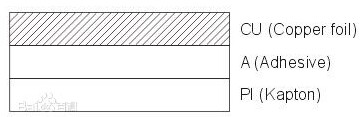

Flexible circuit board structure:

E.D.and R.A.copper foil Cu copper layer. There are three types of copper sheet, RA, Rolled Annealed Copper and ED, Electrodeposited.ED and RA have different characters due to different manufacturing principles.Copper is low-cost but brittle,the copper body is easy to break when doing bend or driver. RA copper manufacturing costs are high but flexible, so the FPC copper foil mainly uses RA copper.

A (Adhesive) : Acrylic and epoxy thermosetting adhesives

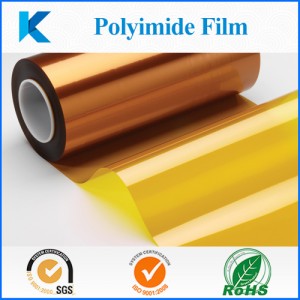

PI (Kapton) : Polyimide Adhesive is divided into Acrylic acrylic resin and epoxy resin. Polyimide is short for PI and is named Kapton in DuPont. It has a unique combination of thin, high temperature and drug resistance, good electrical insulation.

high-temperature carrier film—Solve plicated and useless problems of single-sided FPC board.

Applications:

This product is mainly used for process protection of single-sided FPC , effectively preventing wrinkles, crush, pollution and improve product yield.

PET film

Adhesive layer

PET release liner

Carrier Film consists of three-layer structure, film-adhesive-release liner and the order of use is as follows:

1.Fitting. Remove the release film from the carrier liner, and stick the adhesive to the FPC’s PI surface. It can be used by dry film laminator hand and automation. Pressure:3-4Kg, 90-110°C, speed:1-3 meters. Little control of tension adjustment helps to prevent plates become curling.

2.Paste the dry film, exposure, development, etching, back film, paste covering film, no special instructions for process technology. You can achieve grinding easily because of the enhanced Carrier film, which replaces the previous tape craft.Besides,it can reduce FPC waste caused by falling of the adhesive and enhance productivity.

3.This product is more suitable for the use of traditional lamination process and post-plating process. When applying the fast-pressure process,the pressure should be below 180 degree,and the pressure is no more than 100kg, or FPC would be curly. Gently removed the FPC from carrier film and go on next process once curling occurs. The internal stress of the Carrier film can effectively reduce and FPC keeps straight if you apply traditional pressing process and naturally cool it after compression.

4.Electroplate. Fix the Carrier Film to avoid plication during the electroplate process. The acid concentration of the protective layer is 5%, please test if it is higher than that.

5.Post-processing. Removed the Carrier Film after plating, dry the FPC. Remember that the Carrier Film can not be reused.

Contact us for quote or sample.

FAQ Content