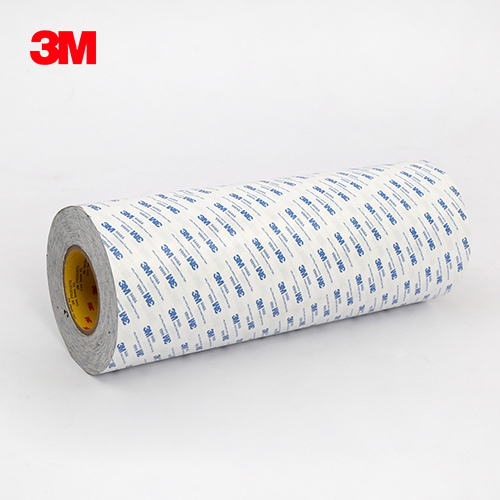

3M 9448A/9448AB Double Coated Tissue Tape

Short Description:

Product Detail

FAQ

Product Tags

Product description

3M 9448A/9448AB Double Coated Tissue Tape is a non-woven fabric substrate double-sided adhesive, non-woven double-sided coated acrylic acid gel made, the high adhesion adhesive provides excellent adhesion to a variety of surfaces. Dimensional stability and improved handling with ease of die cutting and laminating. According to the tape color is divided into different white glue and black glue.

Features

3M Adhesive is a medium-firm acrylic adhesive system featuring both high initial adhesion and good high temperature holding power.

Application Ideas

● Nameplate bonding

● Plastic film lamination/bonding

● Foam bonding

Data sheet (3M 9448)

| Carrier | Tissue |

| Adhesive | Acrylic |

| Color | Translucent/Black |

| Total Tape Thickness | 0.15mm |

| Size | 1200mm*50m |

| Long-term temperature | 80℃ |

| Short-term temperature | 120℃ |

| Adhesion to Stainless steel | 140N/100mm |

| Adhesion to PC | 135N/100mm |

| Adhesion to PP | 105N/100mm |

| Relative solvent resistance | Medium |

| UV Resistance | Medium |

Note : The following technical information and data should be considered representative or typical only and should not be used for specification purposes.

Application Techniques

Bond strength is dependent upon the amount of adhesive-to-surface contact developed. Firm application pressure helps develop better adhesive contact and improves bond strength.

To obtain optimum adhesion, the bonding surfaces must be clean,

dry and well unified. Some typical surface cleaning solvents are isopropyl alcohol or heptane.

Note: Carefully read and follow the manufacturer’s precautions and directions for use when working with solvents.

Ideal tape application temperature range is 70°F to 100°F (21°C to38°C). Initial tape application to surfaces at temperatures below 50°F (10°C) is not recommended because the adhesive becomes too firm to adhere readily. However, once properly applied, low temperature holding is generally satisfactory.

Note: Custom sizes are available upon request and supply free sample for test.

FAQ Content